The industrial standard for 25 years

WS3/5 ET SuperCon Tensioners

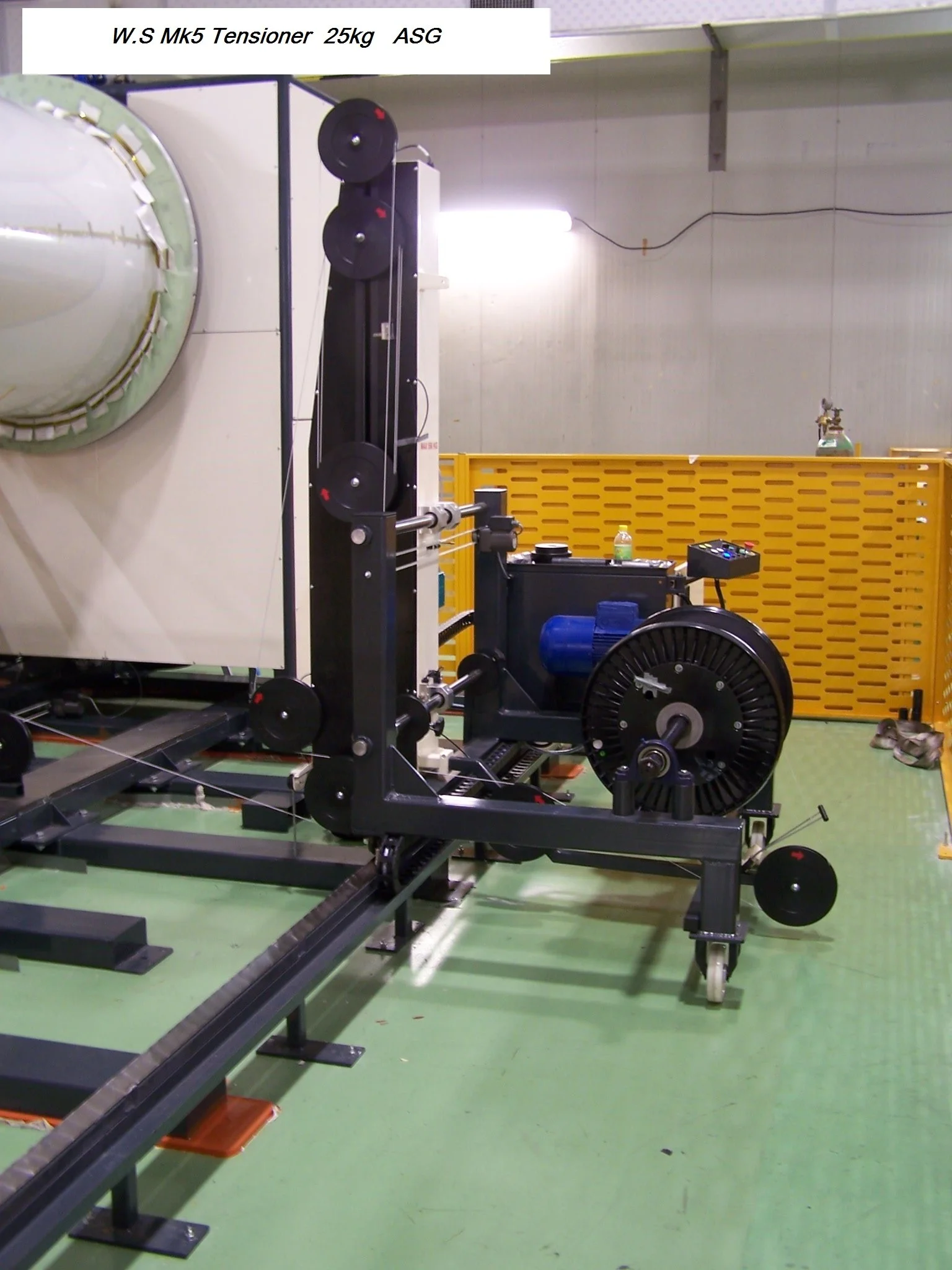

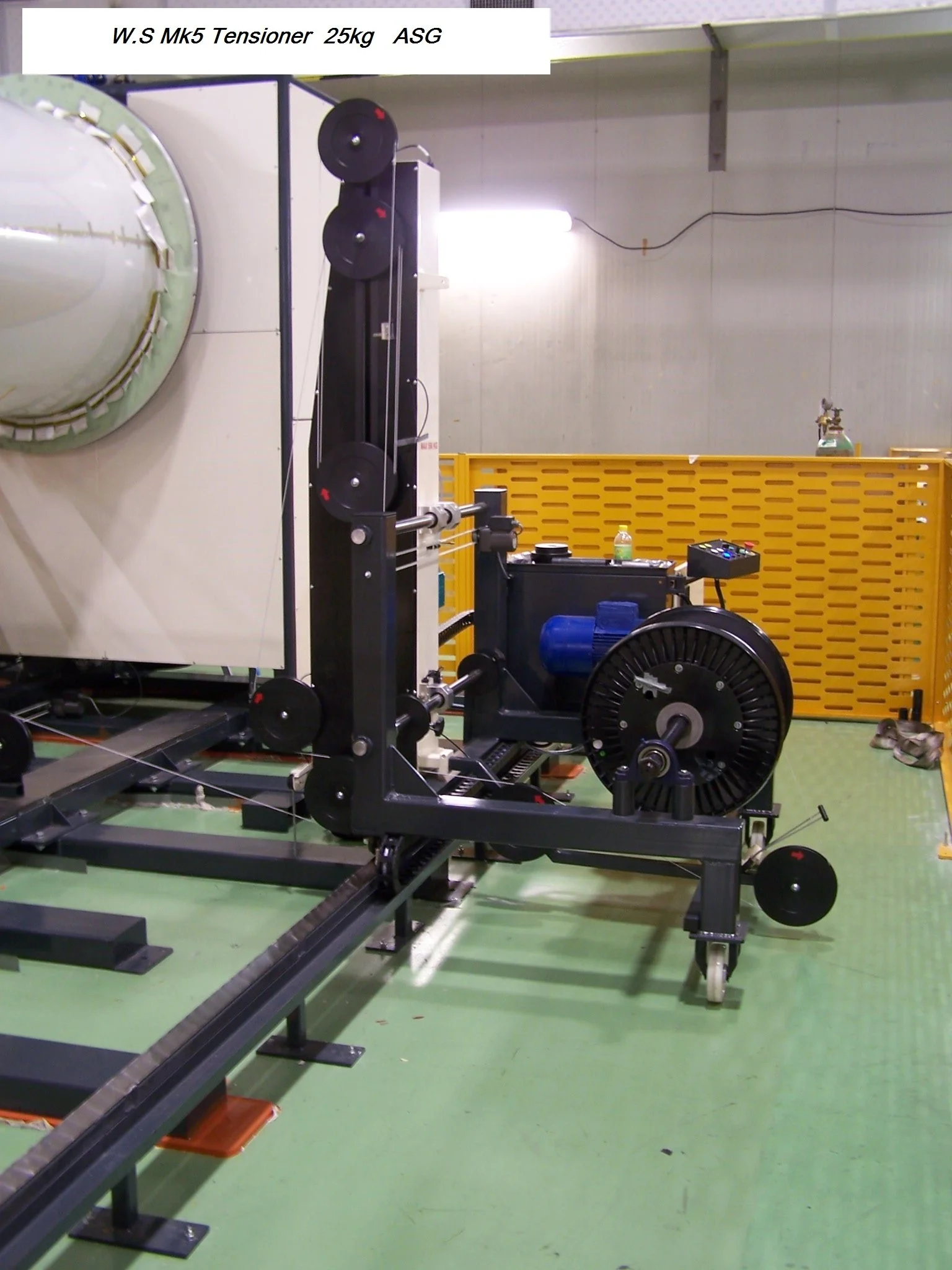

WSET Mk3–5 Closed-Loop Tension Feed Systems

The WSET Mk3–5 machines are complete closed-loop tension feed systems, designed for the feeding and tensioning of sensitive wires or textiles from drums up to DIN 800 and 500 kg.

The Mk3/5 have been specifically developed for superconductive wires, offering precision control and stability during critical winding operations. Each unit is modular in design, comprising three main assemblies: the trackway, the drum platform, and the tension housing.

Construction & Features

Trackway – Supports the platform and tension housing, allowing the platform to move in parallel with the winding machine traverse via rollers and a gear motor. This ensures the wire is fed between the tension housing and winding machine as straight as possible.

Drum Platform – Runs along the trackway, carrying the wire drum, drum drive, rewind traverse, traction gear, and tension housing. It also houses the control and drive units.

Tension Housing – Mounted on the platform via linear bearings, with its own wind and rewind traverse to maintain alignment between the drum and housing. Incorporates the tension drive unit, load cell equipment, and drum drive encoder.

Operation & Control

The operator sets the required tension via a thumbwheel potentiometer or dedicated DGT 300 plc and LED display.

Wire tension is maintained within ±10% of the set value (4% achievable).

Actual tension is continuously displayed on the LED screen for precision monitoring.