Winding Machines You Can Rely On

Winding Machines

Programming & Operation

Integrated 1000-line microprocessor control unit.

Programmable parameters include:

Wire arm start position

Bobbin width

Wire diameter

Total turns

Slow down turns

Wind rotation

Maximum speed

Final turns

Manual operation also available, controlled via the foot pedal.

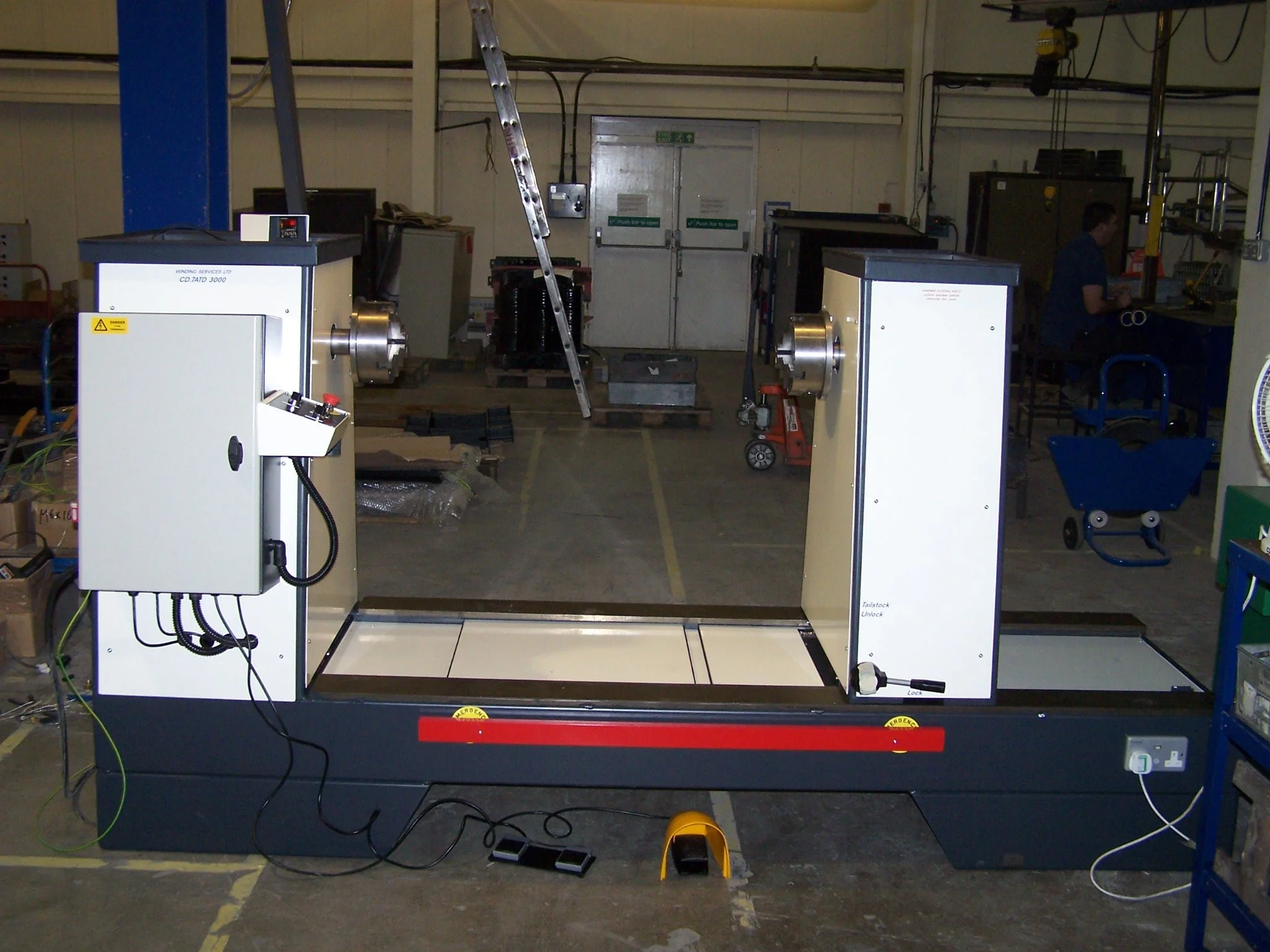

WS2 Bench-Mounted Winding Machines

The WS2c model is a table-mounted, self-contained coil winding machine, equipped with a heavy-duty lead-screw operated tailstock and rear-mounted traverse system.

Construction & Features

Built from heavy-duty 3 mm steel.

Available with AC or DC motors and drives, with power ratings from 0.55 kW to 1.5 kW as required.

Motors fitted with fail-safe brakes.

Supplied with an interlocked frontal guard for operator safety.

Adjustable wire feed arm for angle and length, with aluminium or Delrin “V” pulleys.

Two belt speeds as standard, changed quickly by removing the side cover (no tools required).

Control System

Full CNC, new touch screen version available

Fully enclosed control box and switch panel for safe and easy access to all switchgear.

Choice of foot pedals for standing or sitting operation.

All pedals feature a brake release and comply with the latest low-voltage regulations.

Specifications:

Heavy duty steel construction.

Maximum coil diameter 580mm.

Center distances up to 1000mm.

Capacity up to 1mva.

Traverse length 800mm.

Winding speeds 0 - 250rpm, 0 -800rpm.

Dimensions L - 1657mm, D - 620mm, H - 1220mm

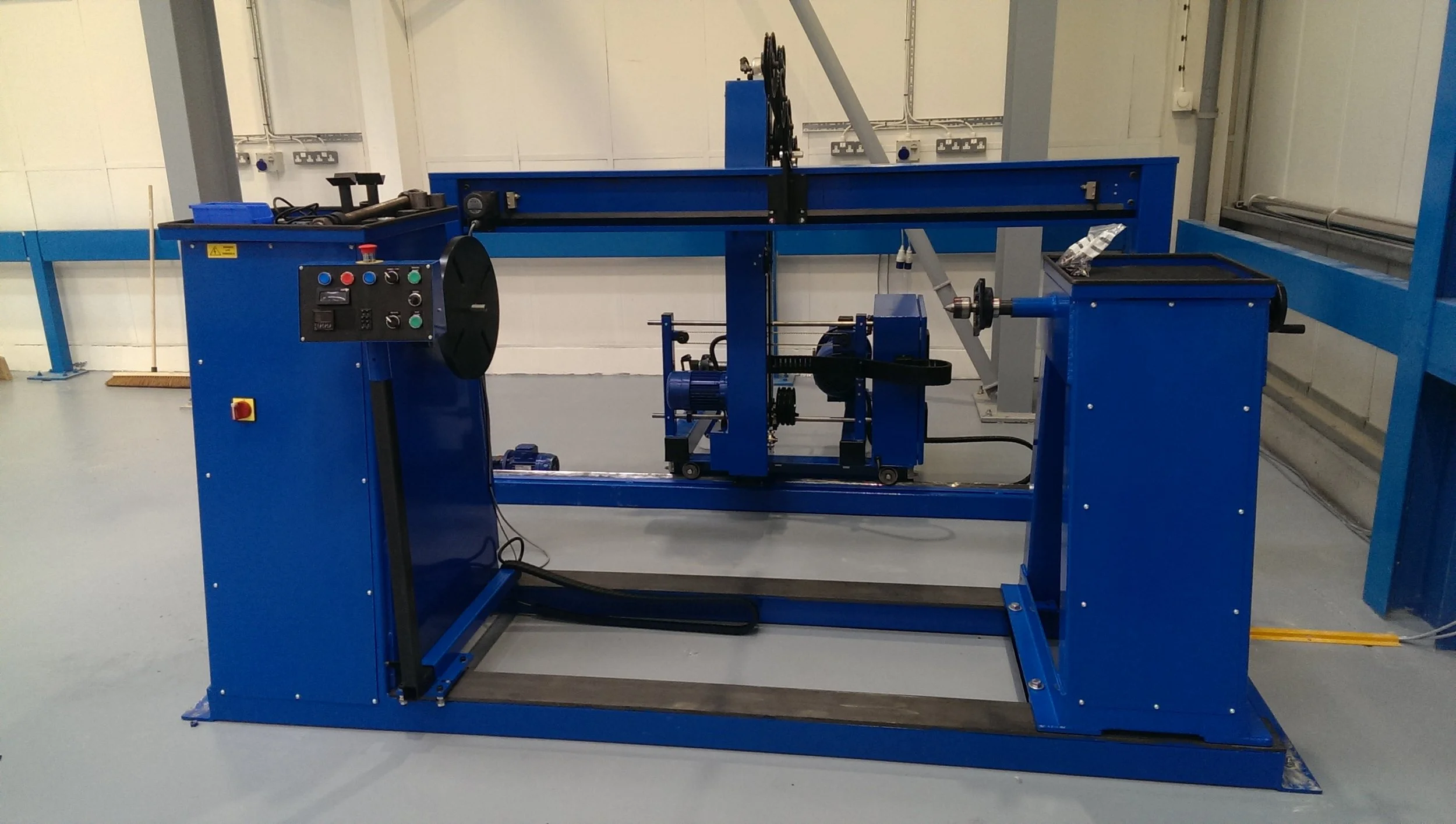

WS5 Series Floor Mounted Winding Machines

The WS5 series is a range of floor-mounted, heavy-duty winding machines, available in four versions. Each machine is built to order, with custom sizes available on request:

WS5a – Free-standing pedestal winding machine.

WS5AT – Free-standing machine with a rail-mounted adjustable tailstock.

WS5b – Free-standing machine with operator table and sliding tailstock.

WS5c – Free-standing machine with operator table, sliding tailstock, and rear-mounted electronically controlled traverse, and full CNC version available.

Construction & Features

Built from reinforced 6 mm steel plate for strength and stability.

Choice of single-speed fixed ratio gearbox or two-speed format.

Fitted with variable speed inverter or AC servo drive.

Motor options from 0.75 kW to 3 kW.

Counter options:

Electronic bi-directional counter (also in tenths of a turn) with:

Single program (slow-down and stop), or

Up to 999 programs (full CNC control).

New WS touch screen controller available on this model

Available with a choice of faceplates or custom spindles, plus two styles of tailstock.

Machine bedway or pedestal can be fitted with plug outlets for soldering irons, grinders, etc.

Control System

Fully enclosed control box and switch panel for safe, easy access to switchgear.

Choice of two foot pedals:

Standing operation.

Sitting operation.

All pedals feature a brake release to allow manual spindle movement.

Specifications:

Heavy duty triangulated box tube construction

Motor sizes 4kw - 10kw

Centre distance 0 - 3 meters

Capacity from 750 kg to 2 tonnes

Hydraulic fail safe braking system

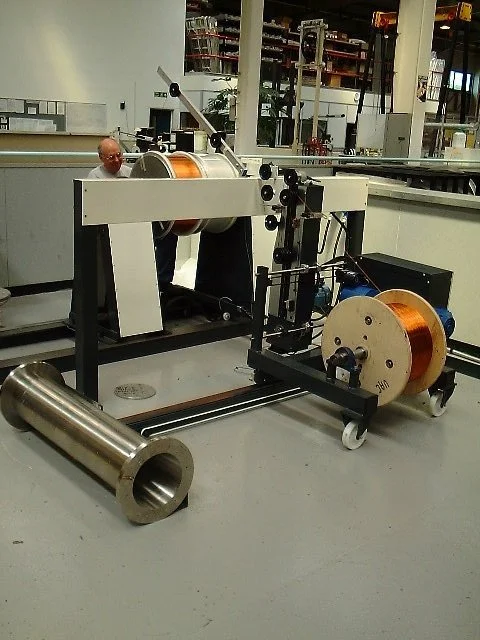

WS7AT Heavy Duty Coil Winding Machines

The WS7 series (a/b/c/dd) has been developed for winding distribution transformers up to 12 MVA or medium-sized body scanner coils. Each model is built to order, with flexibility to include customer-specific features at the design stage.

WS7a – Free-standing pedestal winding machine. With custom faceplates or chucks, it is ideal for winding complex coils where maximum operator access to the inner former is required.

WS7b – As above, but with floor-mounted bedway, runners, and sliding tailstock. Tailstock options include powered opening/closing or a powered spindle for distortion-free double-end drive winding.

WS7c – As specified above, with an integrated or remotely mounted traverse unit. This unit is adaptable to run with WS ET mark 5 tensioner for superconductive winding (as shown in picture)

WS7dd – As specified above, but with a double headstock and synchronised drive.

Construction & Features

Powered by inverter-driven motors and gearbox combinations, tailored to application.

Fail-safe disc braking available across all models.

Winding spindle diameters available from 75 mm to 150 mm.

Control Systems

All models include fail-safe devices as standard.

Traverses can be either remotely powered or integrated with the winding spindle.

The WS7b model remains one of our most popular machines, thanks to the high level of custom specification that can be incorporated at the design stage.

Specifications:

Heavy duty triangulated steel construction

Maximum coil weight 30 tonnes

Maximum between centers 3.7m

Machines built in modular construction for ease of handling

Maximum coil diameter 3.5m

Motor gear unit size 75kw

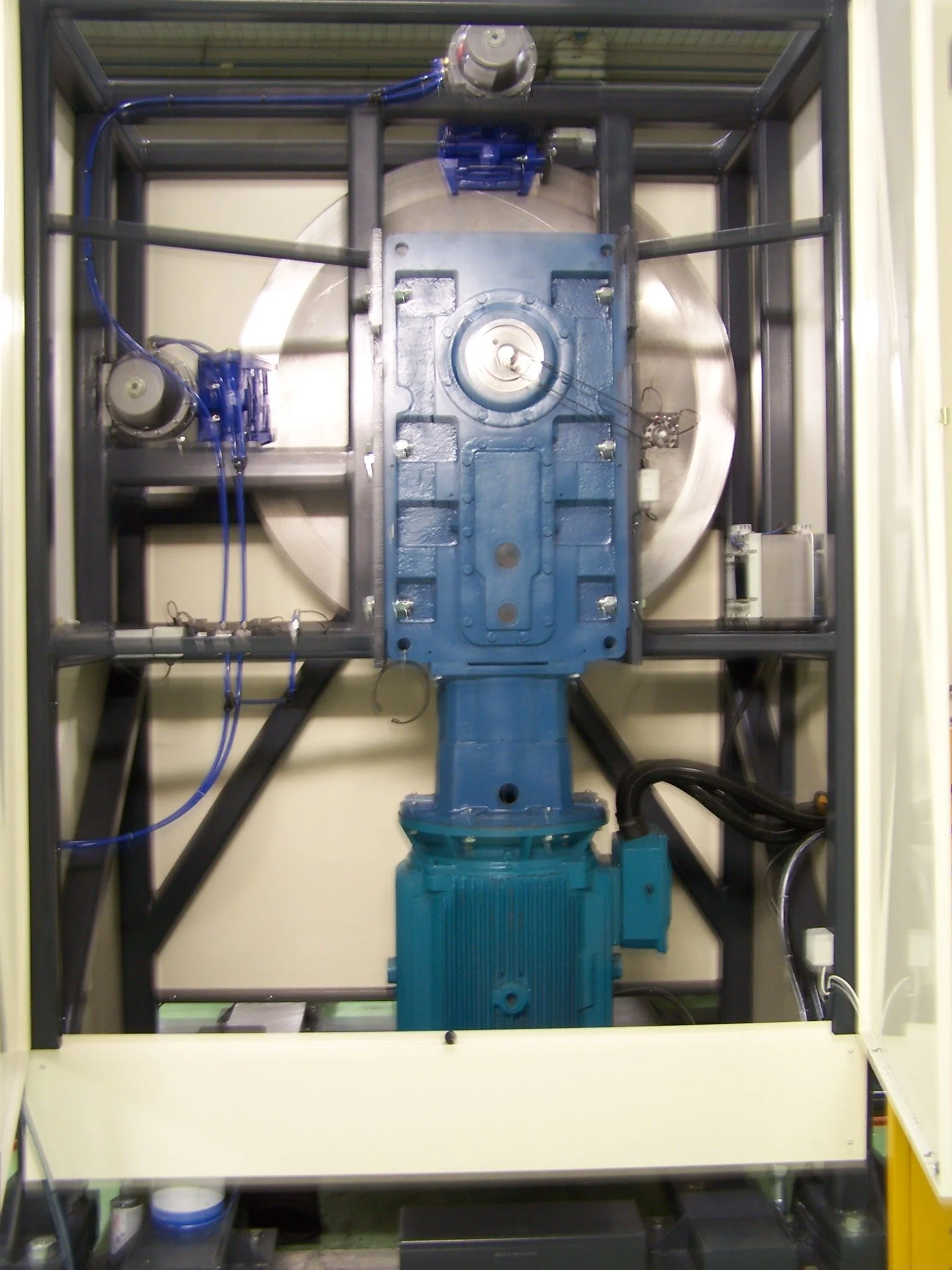

WS12/30 HAT Body Scanner Winding Systems

The WS12/30 HAT series was developed to build some of the world’s most powerful experimental body and scientific scanners. Designed for extreme performance, these machines handle individual coil weights exceeding 30 tonnes and operate at winding speeds up to 27 rpm — making this the largest series we have produced to date.

Construction & Features

Fully integrated, electronically controlled tensioning system.

Safely tensions single conductors up to 27 kg, with wire drum capacities up to 575 kg.

Adjustable operator platform, moveable to accommodate coils up to 3.5 m diameter.

Sliding control box for convenient access as the coil progresses.

Electronic tensioners allow coils to be unwound at the same speed they were wound, with wire layer-wound back onto the spool via the onboard traverse system.

Safety & Control Systems

Equipped with three independent fail-safe braking systems, capable of bringing the machine to rest in under 2 seconds, typically with no ill effect on the conductor.

Full touch screen CNC control available

Machine can be operated from either the platform or the tensioner controls.

Tailstock supplied with manual or powered opening/closing mechanism.