Specialist Machines

Winding services undertakes commissions to design and build machines to cater to customer specific requirements

Case study: Tube Cutter

To design a one-off CNC pipe cutting machine for a major caravan producer in the UK.

The machine had to uncoil, straighten, and cut with no burs copper water and gas pipe.

The cut pipe had to be ejected onto a collecting table.

Their copper pipe was covered with a variety of insulations requiring different cutting programs.

All waste was to be collected in a tray under the machine.

The facility to cut various pipe lengths per batch was to be a feature.

The machine was supplied in two bolt-together units for ease of transportation.

Case study: Spiral Coil

The customer required a machine to form a spiral air coil from 25mm x 4 mm electrical-quality aluminium strip.

The coil had to be open-wound to a close tolerance with no distortion.

The process was automatic, with the operator loading and unloading the strip.

WS assisted the customer in sourcing the correct grade of aluminium through our extensive partner suppliers

Case Study: Respooling Machine

Our customer purchased 30000 spools of very special insulated cable, to be used in a GPS-controlled lawn mower application

The spools arrive from China on SAE-sized spools that our customers’ end users could not process.

We designed and built a spool-to-spool winding machine that allows one operator to wind the material from the non-compilable spools to the correct one.

The machine featured a very accurate meter head.

At the end of winding with correct meterage to the new spool, ten meters remained on the donor spool.

This was then automatically wound onto the hank head in the same cycle.

An on-board compressor was specified to run the machine’s pneumatic systems.

Case Study: MQ Winding Machine

A major supercon supplier required the recommissioning of a machine that had been in very long-term storage.

During storage, the machine’s manufacturer had ceased trading, no technical drawings existed, and the obsolete control package had lost its pc hardware.

The machine was required urgently to fulfill a CERN order.

WS removed the working parts and the existing control package at the customer site. The machine has been too large and heavy to be easily transported.

A new tensioning and control package was designed and installed at our factory.

The moving parts of the machine that previously had little guarding were upgraded with fully monitored interlock guards.

The machine originally ran three-phase 400V motors and actuators through overhead crane-type slip rings.

All these rings were at the operator level and easily touched.

We replaced all the 400V units with 230V or 24V DC where possible, significantly reducing operator risk. RCD is being used.

The newly upgraded system was reinstalled at the customer’s factory with a total turnaround time of under five weeks.

Case study: Double drive fence wire machine

A customer who produces mesh wire fence required a machine to wind scrap SWA armour wire onto drums to sell as single-strand fence wire.

The wire was supplied on open coils 2 meters tall and several tons in weight.

The wire was a min of 3.5mm in diameter and, in winding terms, unbreakable.

An over-end feed system was designed along with a double drive version of our WS5c machine.

The machine was required to be very powerful and robust, with automatic closing interlocked guarding.

A sensor package was fitted to detect wire snags or breakages.

A built-in overhead crane was fitted as all finished spools exceeded the recommended handling weight.

The machine proved so successful that the customer is now a major producer of this product and purchased a second machine

Case study: Micro winder

Our customer produced a range of miniature sensor coils layer-wound onto a 2mm diameter tube.

The product is wound to very tight tolerances. The entire process was undertaken using an extreme magnifying glass and lighting.

This resulted in only one skilled operator in the workforce being able to consistently produce the product.

With quantities increasing, the customer required a machine to automate the process and allow any operator to make the product.

WS designed and built a bench-mounted CNC machine to wind the wire around the tube (now static ) in the style of a toroid winding machine.

The machine exceeded expectations, resulting in production time being reduced with no significant failure rate.

Case study: Automatic Hank Winding Machine

A major electrical cable supply received an order to produce 1000s of 5-10-20-meter length cable hanks.

This overwhelmed their usual production method of manually pulling the cable through a meter wheel onto, at best, a collapsing hub, or worst, from hand to elbow.

WS designed and built a machine to automatically feed the cable into a hank head. Since the cable end and clamp it, wind and layer the correct length, finally cutting and collapsing the hank head.

The resulting machine could process a single core up to 25csa battery cable.

The finished hank only required manual removal from the hank head.

A spool feed roller table was included with the hank taping unit, being a modified one from our supplier partner.

The machine exceeded all expectations, allowing one operator to outperform five in comfort without fatigue.

Case Study: Static and Mobile Supercon Lapping Machines

Our customer required a system capable of applying cloth tape over a hollow superconductive conductor during the winding process.

WS designed, manufactured, and installed a complete solution comprising three quadrupole winding tables, lapping machines, and spool holders.

The coils were wound and layered vertically (z-axis) from the table upwards, with the conductor maintained under a high, consistent tension of 50–100 kg.

Each lapping machine was designed to straighten, tension, and lap the conductor using up to four tape holders. The lap pitch is set electronically, while the angle and tape tension are adjusted manually. The entire lapping assembly moves vertically to maintain alignment with the winding process.

The machines proved highly successful, allowing multiple quadrupoles to be wound efficiently using semi-skilled operators.

Horizontal Winding Development

Following the success of the initial system, the customer requested an adaptation for horizontal winding. This required a heavier-duty version of the lapping machine, with the z-axis manually set and the entire lapper designed to traverse along a trackway in the x-axis.

To support this, the conductor—supplied on 700 kg drums—necessitated the development of a motorised hydraulic drum lifter and tensioner, which also travelled with the lapper along the x-axis.

Building on the success of these machines, WS later developed and integrated an automatic rewind facility, which was subsequently retrofitted to the original systems and incorporated into all new builds.

Case study: Modular guarding.

For many years, it had proved expensive and troublesome to source wall-type guarding for the larger projects we undertook.

This guarding does not protect the moving parts of the machinery directly but is used to provide a perimeter to define the working area of the larger machine.

Typically, to protect third-party personnel or the storage of factory items in an area not obviously used by the machine.

To this end, in partnership with a supplier, we produce modular guard panels, posts, and interlocked gates that exceed the usual temporary barriers often used.

These panels are made to order and will finish any project with a professional look.

Case Study: Cable Stripe / Dyeing Machine

For many years, several customers have continued to use an obsolete cable striping machine design dating back to the 1960s–70s.

In the original process, the cable passed over a knife-edge roller dipped in ink, coating it as it moved through the system. The cable then travelled through a heat chamber to cure the ink before being air-cooled and rewound onto a new spool.

However, these legacy machines had significant drawbacks. They lacked any cooling system for the heated cable, offered no extraction for the now-regulated volatile fumes, and had no guarding or safety provisions whatsoever.

WS was approached by a new customer seeking a quotation to upgrade one of these ageing machines. After inspecting the equipment, we advised that a complete redesign would be more effective — resulting in the development of the WS Cable Processing Machine.

The new design retains the proven rotating-wheel striping method but incorporates a range of modern enhancements, including:

Automatic ink tank refill system, replacing the previous open-jug method.

Integrated cooling chamber for safer, more consistent processing.

Programmable controls for precise operation and repeatability.

Full fume extraction for operator safety and environmental compliance.

Stainless-steel construction, eliminating staining issues found with powder-coated surfaces.

Low-voltage operator lighting for improved visibility and ease of use.

The WS Cable Processing Machine modernises an outdated process to current standards while maintaining the functional advantages of the traditional method.

Although inkjet marking systems are available, they remain limited in colour range and are prohibitively expensive to purchase and operate. As a result, the traditional striping process — now refined and made safe through WS innovation — continues to offer a practical and economical solution for cable suppliers.

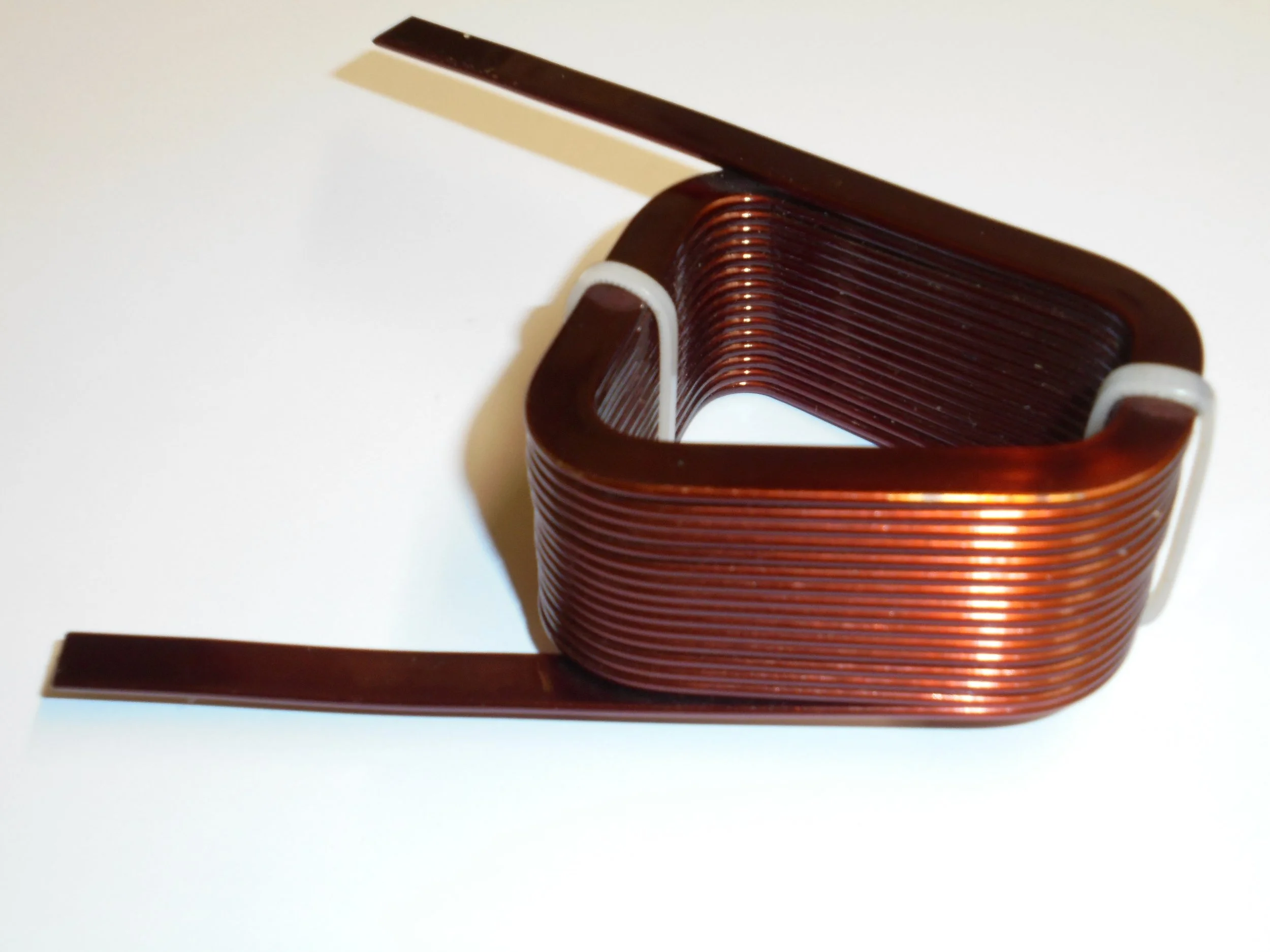

Case Study: On-Edge Motor Stator Coil Forming Machine

A customer required a machine capable of automatically forming 6 × 1 mm copper wire into trapezoidal stator coils.

Previously, the customer relied on specialist imports from the Far East for pre-production coils. These were costly, had long lead times, and limited the ability to refine designs during motor development.

WS designed and built a dedicated coil-forming machine to enable on-site production of the coils. This allowed the customer to make subtle design modifications during the prototype and pre-production phases.

The coil specification was extremely demanding, requiring three distinct lengths and two precise angles in each coil. The finished product needed to be delivered in a closed-wound form, with minimal material expansion on the inner bend radii. The coils had to be slip gauge accurate

The portable CNC WS machine supplied wire from 150 kg drums via a powered roller system, feeding the material under neutral tension into the guarded forming head. Within this section, the system automatically measures and forms the required lengths and angles to specification.

The introduction of this machine reduced production costs by approximately 90% and gave the customer full in-house control over coil manufacture, enabling rapid development and flexible, on-demand production.