CNC Control Systems

CNC control system upgrades

Developed in partnership with our leading suppliers.

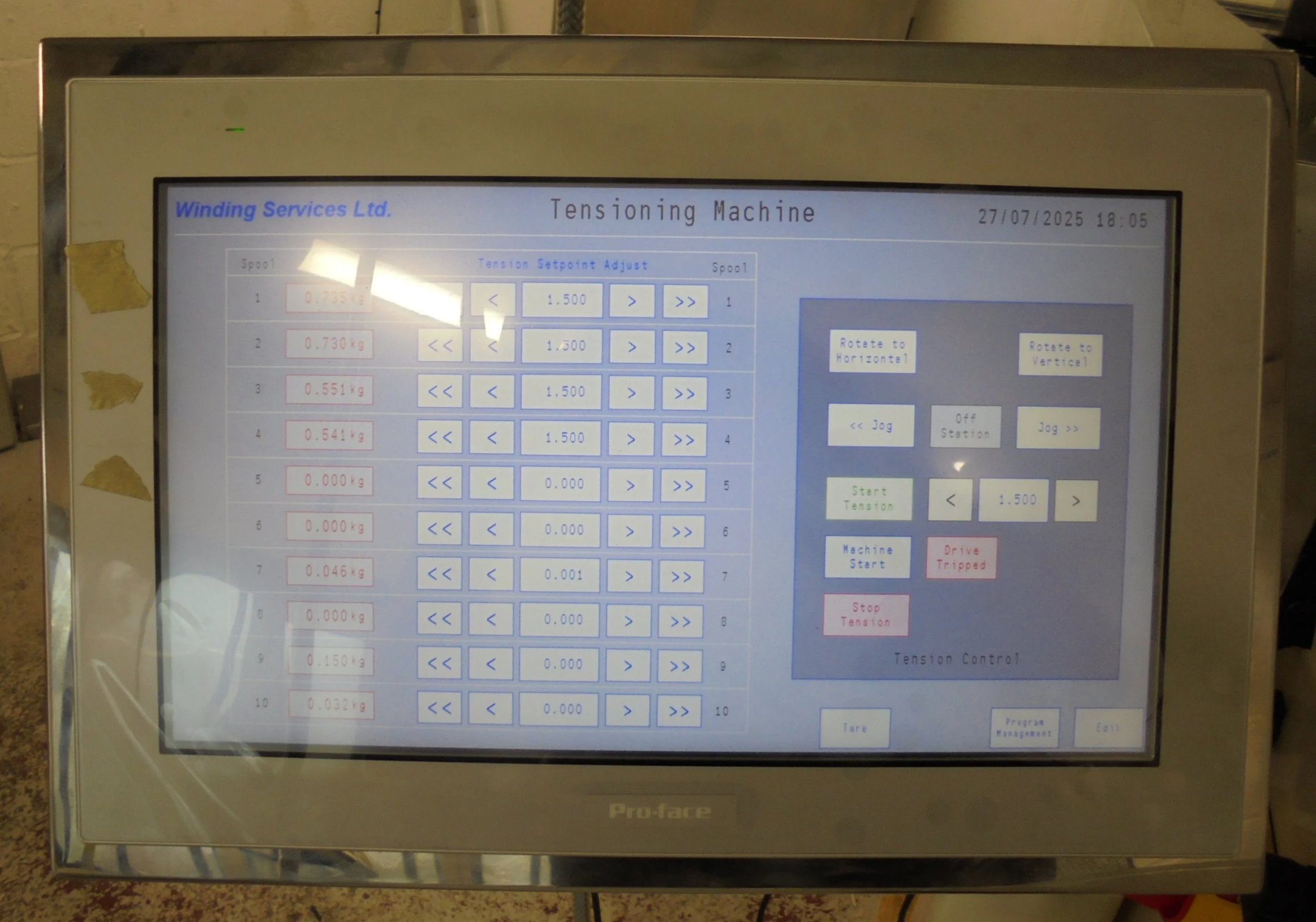

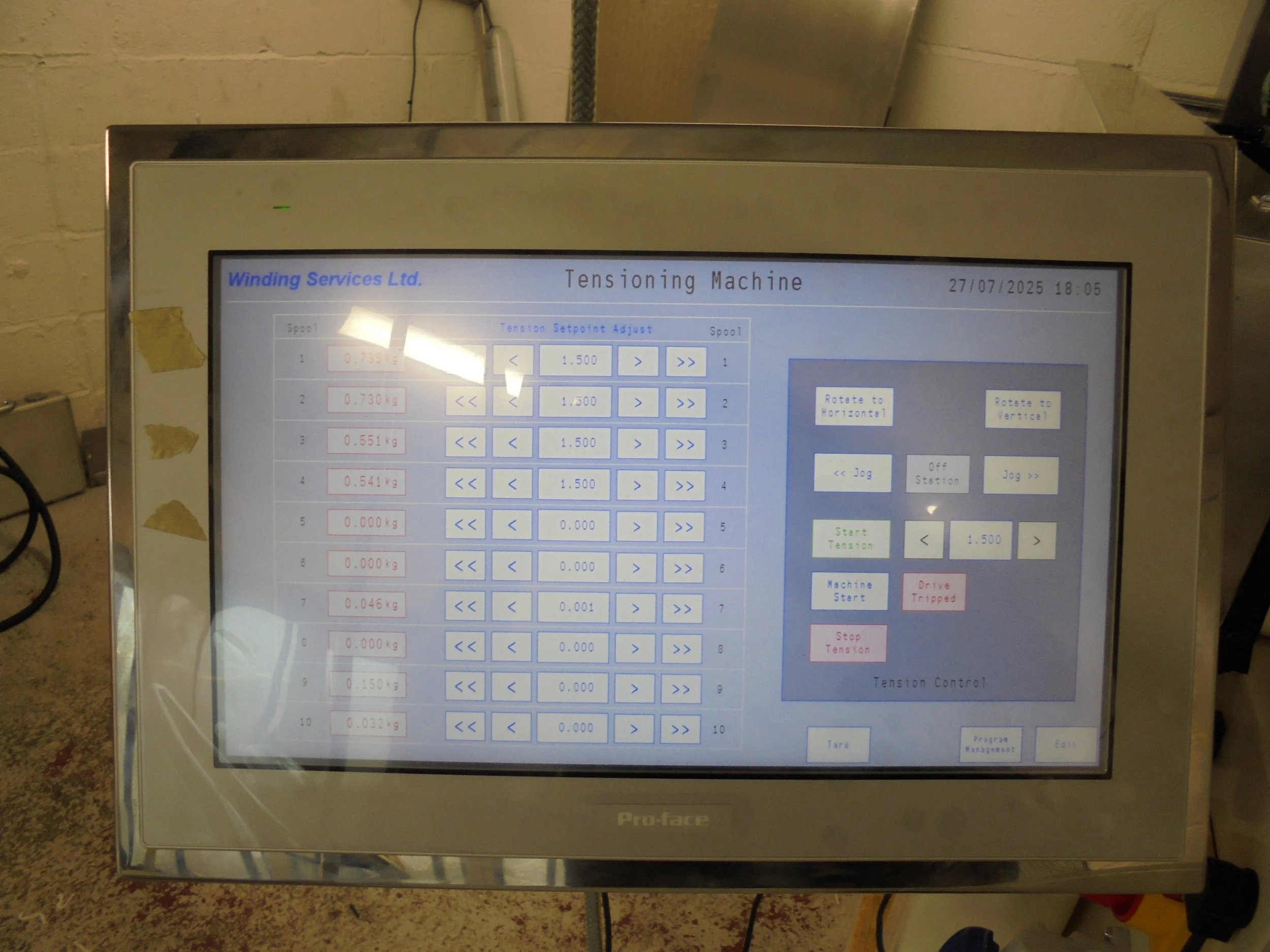

The new WS Touchscreen CNC Winding and Tension Control Units build upon the proven success of the CNC200 range.

Designed with precision and usability in mind, the WS Touchscreen system allows operators to monitor all key winding parameters in real time as the coil is being wound. This enables fine adjustment of the CNC settings, ensuring exceptional accuracy throughout the process.

This level of control has proven invaluable when working with high-end conductors where only a single, flawless winding pass is permitted.

When integrated with any of our Supercon Winding Machines and Tensioner Systems, the operator can monitor and control both units from a single, highly visible HMI interface.

Each WS unit is constructed using the latest Mitsubishi or Pro-face components, ensuring reliability, performance, and long-term support.

CNC200 Series Controllers

The CNC200 Series has become the go-to worldwide controller for mid-priced winding machinery.

Originally manufactured in China, the units supplied to Winding Services are upgraded with enhanced programming features, offering improved performance and user flexibility.

These controllers serve as direct replacements for similar systems fitted to many existing Far Eastern machines — some of which have now been in service for over 25–30 years.

By integrating the CNC210 into our control package during a rebuild, we provide users with maximum versatility. The newly refurbished machine can operate in full CNC mode or switchable manual control, offering the best of both worlds.

WS 3 machine fitted with CNC 210 in custom housing